|

UTTsolar New Material Research Lab focuses on developing a new composite material, which is called Xcompo, which is made from glass fiber and polyurethan resin. This new material is widely used in the buildings along the coast, power transmission tower, bridge, container baseboard, offshore oil drilling platform and chemical factories due to its special properties. Currently, Xcompo can be made into a high strength, corrosion resistant and electric insulated solar frame which help to ensure the security of pv system and the application in the severe environment.

Xcompo frame features

*Electrical insulation

1.The Xcompo frame is integral insulation, the insulation won't be affected if the frame surface damaged.

2.Volume resistivity can reach 1.5б┴10 14ж╕бдcm .

3.The class of insulation is as same as ceramic,transformer oil,silicon rubber,silicone oil,polyvinyl chloride, nylon, etc.

4.The insulativity of frame is able to not only avoid the electric leakage and induction stroke damage to module but also enhance the anti-PID ability of module.

5.Save the grounding wire and components. Reduce the installation steps and costs.

*Corrosion resistance

Xcompo can bear the corrosion of different levels of acid, alkali, organic solvents and salt, and many other of the corrosion gas and liquid mediums. Xcompo frame is quite suitable for PV plant in intertidal zone along the sea, volcanic ash area, island, desert and chemical industry roof, because it has a strong corrosion resisting property to the volcanic ash, sea wind, sea water etc.

*High strength

The tensile strength of Xcompo is about 1200Mpa,5 times stronger than aluminum alloy. The module assembled with Xcompo frame can completely withstand pressure of the wind load and snow load. 1582x1062 and 1642x992 modules both can pass the mechanical loading test and withstand 5400 pa pressure for 24 hours, the frame height is 40mm. After the test, the Xcompo still keep no change.

*Aging resistance

Xcompo has the three-dimensional net structure. It is a compact structure which has a excellent resistance to oxidation and aging. Xcompo successfully passes the 60kwh UV test. The outdoor service life is more than 30 years.

*High-low temperature resistance

Xcompo is able to resist extreme temperature(-70~120oC), during that temperature range, the mechanical properties of Xcompo is almost not affected by temperature. Moreover, due to its compact structure, it can be used in high humidity environment.

*Low thermal expansion

The coefficient of linear thermal expansion of Xcompo is lower than aluminium alloy and is close to glass. So, expansion caused by heat and contraction caused by cold won't cause the deformation which may damage the laminate.

*Flame retardancy

According to the requirements of ASTM E162 standard in IEC61730, Xcompo can meet the requirements of high polymer material for solar module frame.

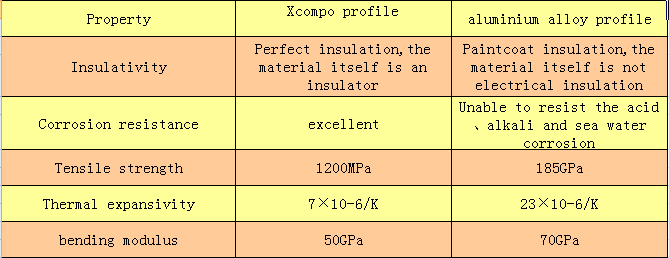

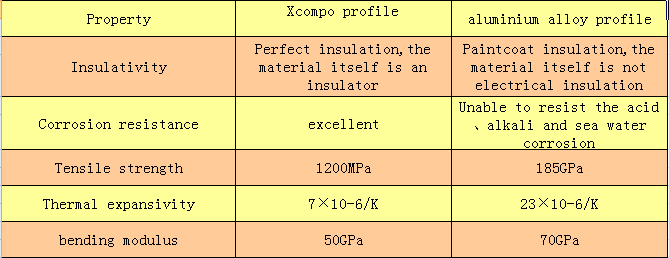

Comparison between aluminum profile and Xcompo

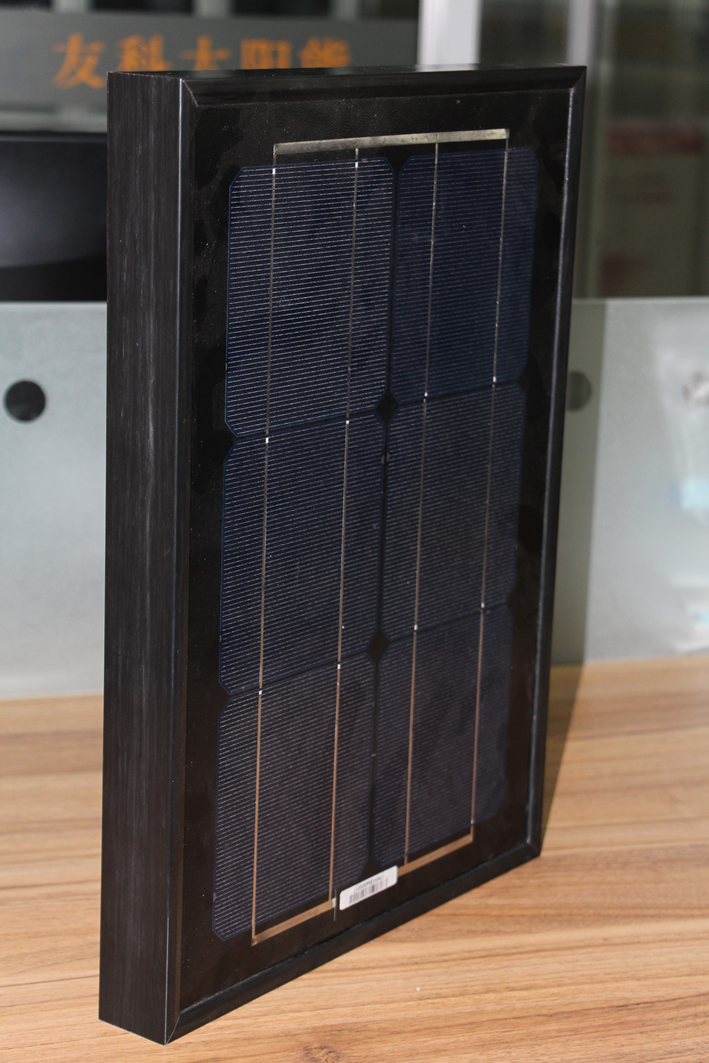

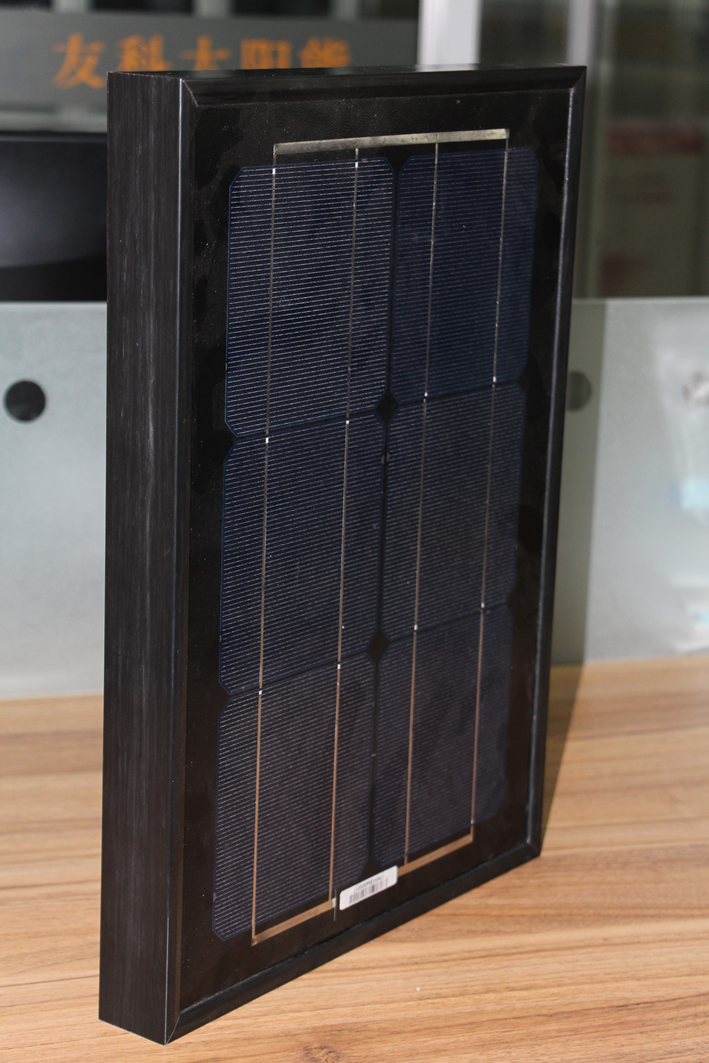

Perfect outlooking:

We can find that using the structure of Xcompo frame is similar to the aluminum alloy frame,which can meet the general requirements of frame assembly process.The connection between mounting bracket is the same as aluminum alloy frame.The installation of solar module can be finished fast and easily without any additional traning.After installing solar panels, Finely connected with the Xcompo frame . It looks very beautiful,concise and fastness.

|